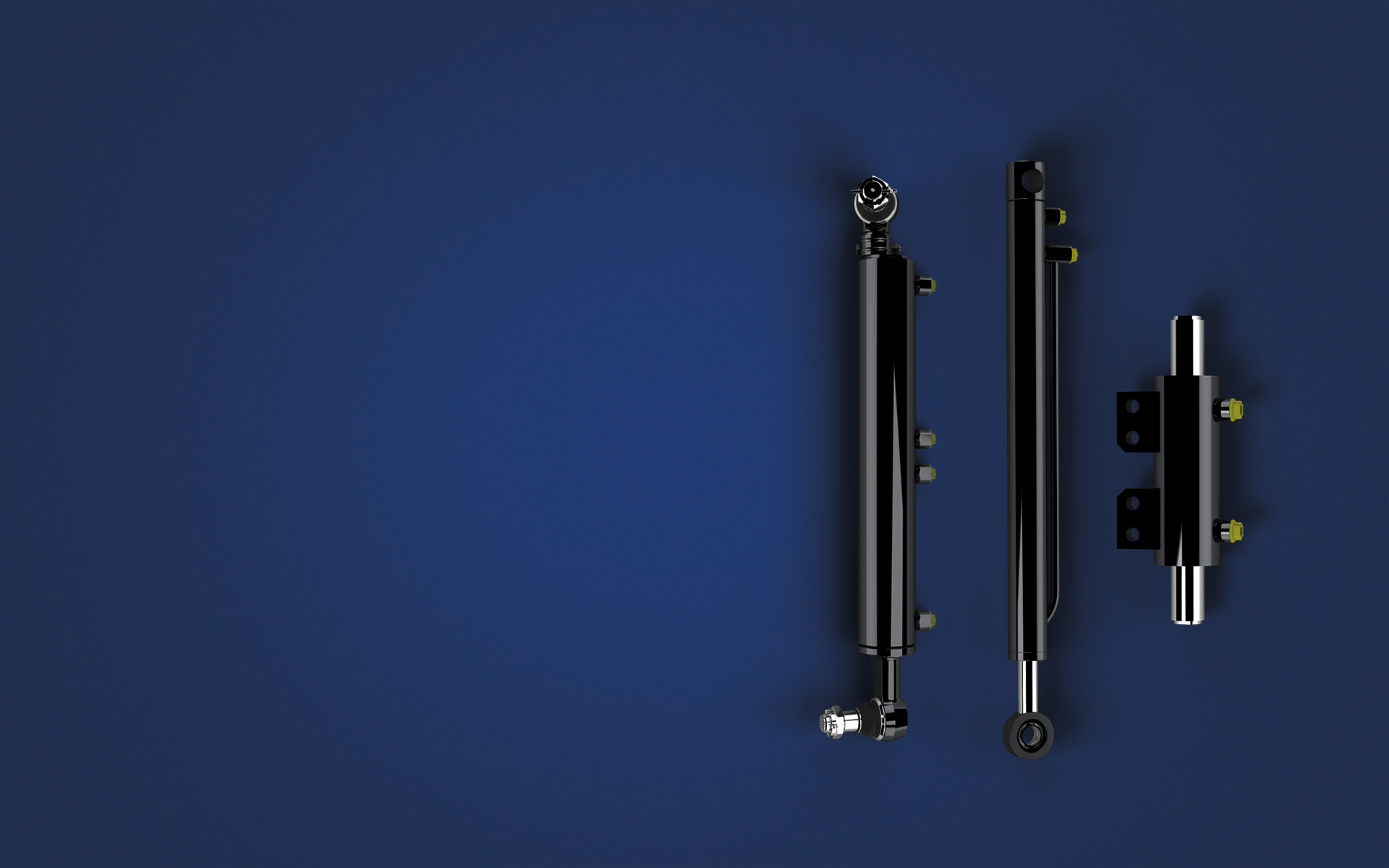

Quality focused Hydraulic Cylinder Production

ROTA produces its hydraulic cylinder through a production process, where each step is standardized and validated. Products are validated after field tests which are carried out under the real-life conditions. Once produced, products undergo a tightness test and controlled for sizes before shipment.

ROTA started to produce steering system hydraulic cylinders for commercial vehicles and tractors. Also ROTA added top-link hydraulic cylinders for tractors and mechanical motion cylinders for agricultural equipment to its production portfolio.

Design

A standardized, validated and optimized cylinder design

Validation

A computerized design validation with FEA analysis

Static and dynamic tests to the automotive production standards

Field tests under the real-life conditions

Production

Production processes developed thanks to experience more than 50 years

A welding process exclusively design for cylinder production

Cleaning with industrial methods

All parts are cleaned with industrial methods before both welding and assembly

Assembly

Hydraulic Cylinder assembly; made by qualified personnel on the special designed assembly line.

Control and test

%100 tightness test up to 500 bar with filtered oil according to ISO 4406 CE 18/15/12 standard

%100 size control of all critical characteristics, in addition to the performance test

Surface protection

A minimum hours of corrosion resistance with wet paint over nanophosphate in the paint shop according to EN ISO 9227 standard.

Packaging

A packaging preventing potential damages during handling and transportation.