Hot Metal Forging Factory

Our Hot Metal Forging Factory carries out its productions in Karacabey town of Bursa city on a total area of 5,000 m2 with 4.500 m2 indoor area.

Our factory has a forging capacity of 12,000 ton/year, equipped with friction presses and gravity hammers. Our Hot metal forging factory manufactures carbon and alloy steel parts in various sizes and shapes, weighing from 0,25 kg up to 20kg.

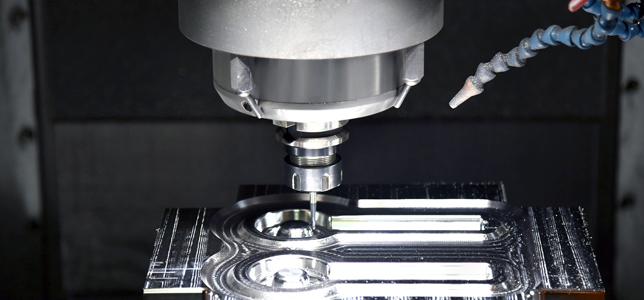

Our factory also has the capability of machining, producing machined parts. Also, it has the capacity of producing rubber metal parts with state-of-art surface treatment and vulcanization machinery pool.

1

Our Hot Metal Forging Factory carries out its productions in Karacabey town of Bursa city on a total area of 5,000 m2 with 4.500 m2 indoor area.

Our factory has a forging capacity of 12,000 ton/year, equipped with friction presses and gravity hammers. Our Hot metal forging factory manufactures carbon and alloy steel parts in various sizes and shapes, weighing from 0,25 kg up to 20kg.

Our factory also has the capability of machining, producing machined parts. Also, it has the capacity of producing rubber metal parts with state-of-art surface treatment and vulcanization machinery pool.