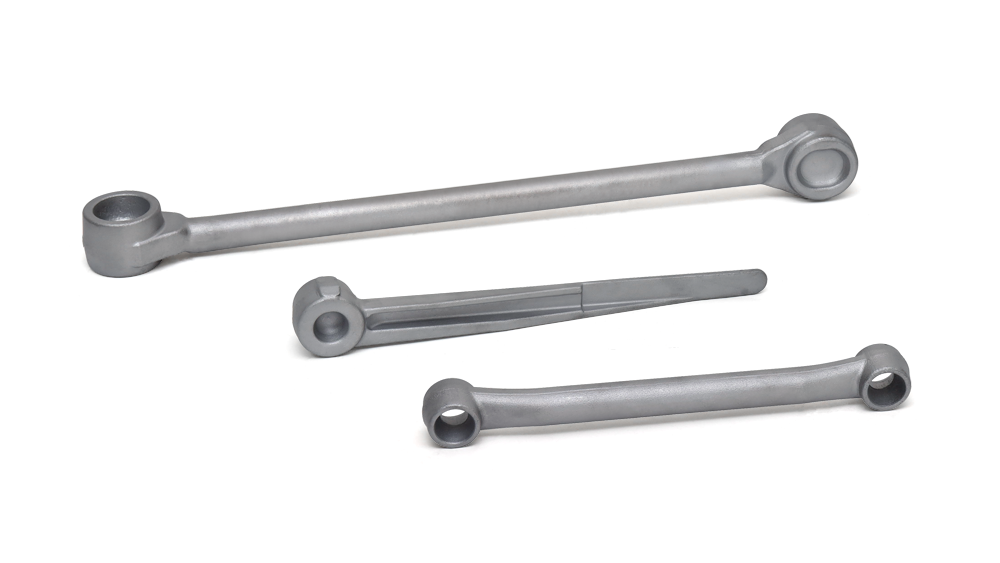

Open-die Forged Parts

Open-die Forging is a metal-forming process where hammers, presses and upsetting are used to give its shape to a metal part. Workpiece is first heated to the deformation temperature before forging it to the desired shape. This is an important method for different manufacturing types as it allows shaping of the common metals such as steel and steel alloys. open-die forging has many advantages since it is low-cost and generally formation of stronger part. In open-die method, workpiece can be forged in many directions.

Since there is no closed mold which will limit the material flow, precision of the workpieces are relatively lower, and may generally need to be completed with rough machining and finishing to meet the tolerance requirements of final parts.